Now you’ve learned the What, How, and Why – learn how it all comes together. It is a critical, thorough process – and one that we do well. If you do not choose us, make sure that the steps and procedures below are followed in order to create a successful assessment. We are finding out that too many engineering firms are taking shortcuts or are not up to date on the latest standards and regulations. Finding an engineering firm that has a strong track record and one that specializes in Safety Engineering will ensure that your Arc Flash Risk Assessment is accurate thus keeping workers safe and keeping you and your team from being held liable from OSHA or other litigation.

Perform a site visit for existing facilities or when performing the required 5-year update.

All equipment must be verified. It is not as simple as rerunning the calculations. This will ALWAYS be the case with any study update. A site visit is critical in order to ensure all equipment is taken into account. If the company you hire states that they do not require a site visit or do not show up for one, it is a big red flag and they are not performing the due diligence needed to make sure the study is accurate.

Determine worst-case bus configuration and measure all enclosure sizes (transformers, panels, disconnects, everything). Recent changes to the IEEE 1584-2018 now take into effect enclosure sizes and this information will drastically change the incident energy levels as discussed in the previous blogs.

It is important to get dimensions rather than using the software “defaults” because the defaults will oftentimes yield higher than necessary IE values (results in too much PPE) and sometimes even lower (results in too little PPE)

Analysis

When seeking an arc flash hazard analysis, require that the parties offering the service have a Registered P.E. on staff and, where required, that the firm is authorized by the state to provide engineering services. Examine the experience and qualifications for conducting the analysis. Furthermore, insist or require in the RFP that they review and P.E. stamp the report to make sure they believe in their findings and that they will bet their career on it. If you intend to use in-house engineers, prepare to dedicate the time and resources necessary to complete the work and to accept full liability for the outcome of the work.

Lastly, the company performing analysis must be up to date and using software with the new 1584-2018 calculation capability. Most (if not all) reputable software has this, however, the firm must know how to input the data and parameters for the proper output).

Label installation

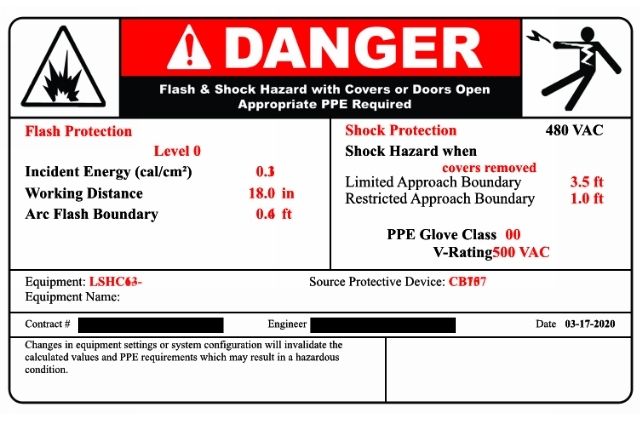

Once analysis is complete using the new standard, labels must be installed again at electrical equipment detailing the newly derived AF values. A lot of changes from NFPA 70E have been made to labels in the past 6 years. Again, make sure the company you hire to perform your assessment is up to date on all standards and regulations. Just the other day, I came across this label on an assessment that was done in March of 2021.

To be honest, I didn’t know where to start picking this apart. At first glance, you notice there are text overlapping that prevents you from reading the values. The biggest thing that stuck out was the Flash protection was at Level 0. That was removed from the incident energy PPE table in the NFPA 2018 version. That was 2 versions ago! This guarantees that the study was not performed to the IEEE 1584-2018 thus leaving the study to be inaccurate and out of compliance. Another reason to make sure you hire an experienced Safety Engineering firm for arc flash risk assessment.

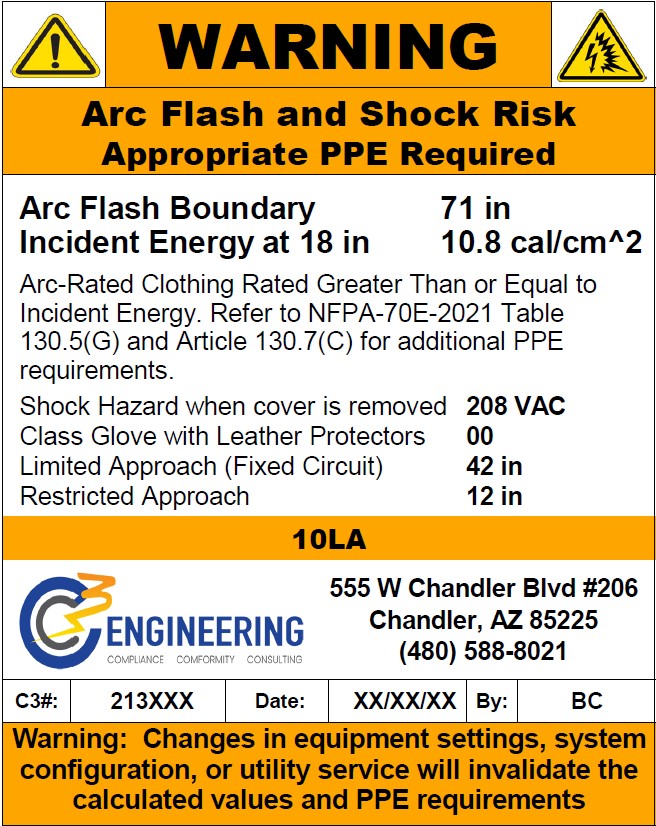

At a minimum, these labels must contain the nominal system voltage, the arc flash boundary, and at least one of the following: the available incident energy and the corresponding working distance or the arc flash PPE category found in the PPE category tables, the minimum arc rating of clothing, or the site-specific level of PPE according to NFPA 70E. Though it is not required, we highly recommend you include the date the study was completed and the company contact information on who performed the work. It is also good to have the initials or name of the engineer on the label as well. The following is a sample of one of our labels and explanations of all the fields.

Lastly, to ensure accuracy, the company that performed the study should be the ones labeling the equipment. We don’t recommend it, but It can be done by the customer. If so, make sure whoever is installing labels understands what label goes where. It is common to find previous studies that were labeled by customer or electricians only to find that all the time and money spent was ruined by this last critical step.

If you need any help developing an effective Arc Flash study, please contact us. We have extensive knowledge of electrical safety as this is our only focus. Many other engineering firms perform arc-flash risk assessment studies as filler work and do not possess detailed knowledge of the standards and how to apply them correctly. We have seen customers get burned by having these types of firms perform their studies for a bargain price later to come back to us to completely redo the analysis.

Next month we will dive in deeper and showcase studies the effects of the IEEE-1584-2018 has had on studies that have been updated since the change has come out.