What Companies Should Know About Arc Flash Studies

Commercial and industrial facilities across the country understand the importance of maintenance for electrical equipment and power systems. Part of that maintenance is a professional assessment by a third party to ensure the safety of the systems, which is where arc flash risk assessment comes into play. Learn more about what you should know about arc flash studies, why they are important, and how to obtain an assessment for your facility.

What is an arc flash study?

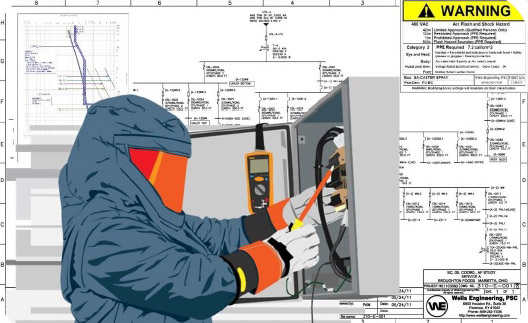

An arc flash study, also referred to as an arc flash risk assessment, is a study conducted by a trained electrical safety expert to evaluate electrical equipment and power systems in order to predict the potential for or incident of an arc flash. The arc flash is the light and heat from an explosion. Temperatures of an arc flash can reach as much as 2,800 to 19,000 °C (5,000 to 35,000 °F). The information from this assessment can be used by companies to effectively train employees on the hazards associated with their job responsibilities and to identify the Personal Protective Equipment (PPE) necessary to keep workers safe in an arc flash incident. PPE can be used to effectively shield a worker from the radiation of an arc flash if used correctly.

What causes an arc flash?

One of the causes of arc-flash is voltage spikes, resulting from switching reactive loads or lightning strikes. The spike or “transient” might last mere microseconds, but it can carry thousands of amps of energy. If this happens while measurements are being taken, a plasma arc can form, either inside the measurement tool or outside. Other causes of arc faults include situations such as:

- Touching a test probe to the wrong surface

- Worn or loose connections

- Corrosion

- Gaps in insulation

- Improperly installed parts

- Dust or debris

Proper precautions to protect workers from such incidents can be revealed through an arc flash study.

Creating a safe work environment through assessments

Understanding the severity of the risk involved with electricity, many facilities are developing an Electrical Safety Program (ESP) their employees can follow to reduce shock and arc flash exposure working about electrical equipment. While signage such as warnings about shock hazard are a good first step, more needs to be done to create a safe work environment. Prevention is always the absolute best way to keep a work environment safe and to protect workers from serious harm or death. PPE also a good step, but improper use of PPE can exacerbate arc-flash hazards and in some cases, no amount of PPE can protect a worker from an arc-flash. Further, Guidance for this is provided by the Occupational Safety and Health Act (OSHA) of December 29, 1970, which states “An Act: To assure safe and healthful working conditions for working men and women…’’ Section 5 of the Act goes on to state that an employer “shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees”. OSHA 1910.132 General Requirements, under Subpart I, Personal Protective Equipment: Section 1910.132(d)(1) states “The employer shall assess the workplace to determine if hazards are present, or likely to be present, which necessitate the use of personal protective equipment (PPE)”. Section 1910.132(d)(1)(i) states the “employer shall select, and have each affected employee use, the types of PPE that will protect the affected employee from the hazards identified in the hazard assessment”.

OSHA recommends that employers consult consensus standards such as NFPA 70E-2018 to identify safety measures that can be used to comply with the requirements of OSHA’s standards for protecting employees from the severity of arc flash hazards: NFPA 70E-2018 Article 130.5 identifies that an arc flash risk assessment (arc flash study) shall be performed to determine if an arc flash hazard exists. If an arc flash hazard exists, the risk assessment (arc flash study) shall determine the arc flash boundary where the arc flash ‘incident energy’ is no greater than 1.2 cal/cm2; a.k.a. Arc Flash Boundary. For any worker inside the arc flash boundary and exposed to energized electrical equipment, or any workers verifying the electrical equipment is at a ‘zero energy state,’ those workers shall wear the appropriate arc flash and shock PPE as required based on their working distance. Also, the results of the arc flash risk assessment (arc flash study) shall be documented and maintained by the equipment owner/employer.

Owners of facilities are likely aware of their liability when it comes to workplace safety and the role they play. NFPA 70E-2018, Article 130.5(D) Equipment Labeling states “The owner of the electrical equipment shall be responsible for the documentation, installation, and maintenance of the field marked label’. The article also states the field-marked label shall contain: (1) Nominal system voltage; (2) Arc Flash Boundary; (3) At least one of the following: a) Available incident energy and corresponding working distance…, b) Minimum arc rating of clothing, c) Site-specific level of PPE.

What is involved in an arc flash assessment at a facility?

The on-site arc flash study done by a power system engineering company consists of arc flash equipment labeling, fault current and coordination analysis, recommendations for improvements and requirements for proper personal protective equipment (PPE). A review and analysis of the facilities’ written electrical safety program is typically included as well. NFPA 70E states that the goal of an arc flash risk assessment is a three-step process:

- Identify any hazards.

- Assess risks.

- Implement risk control according to the hierarchy of risk control methods.

In other words, an assessment should recognize, measure, and mitigate and potential issues that can result in an arc flash. The results of an arc flash study should also eliminate or substitute risk, raise awareness, provide training, and select the proper equipment for the job.

If your facility deals with electrical equipment, it’s critical to have an arc flash assessment done, and update it at a minimum of every five years, or if there are any changes to the electrical system. Also make sure that assessment is performed up to the latest NFPA 70E and IEEE 1584 changes. Arc flash studies protect workers to ensure a safe work environment for everyone.