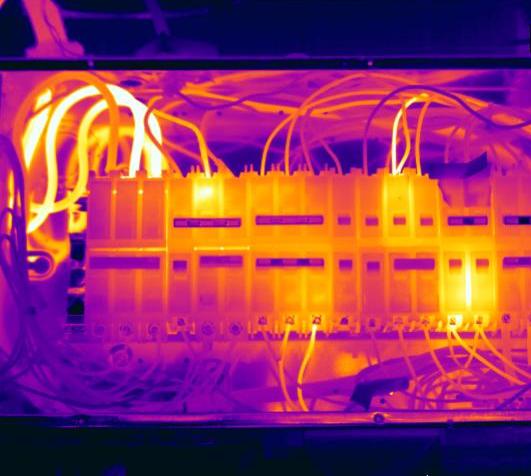

The leading cause of fires in facilities is electrical failure. Infrared Thermography (IR) is great for spotting a lack of uniformity in equipment by indicating hot and cold spots in surface and ambient air temperature, through infrared image capture. Heat is often an early symptom of equipment damage or malfunction, making it one of the most important and cost-effective element of a successful preventive maintenance program. Even better, thermography is non-destructive and typically requires minimum access to electrical components.

Thermography measures surface temperatures by using infrared video and still cameras. These tools see light that is in the heat spectrum. Images on the video or film record the temperature variations of the building’s skin, ranging from white for warm regions to black for cooler areas. The resulting images help the auditor determine whether insulation is needed. They also serve as a quality control tool, to ensure that insulation has been installed correctly.

Read more about thermography inspections from the US Department of Energy